Press Release

-

March 20, 2025 · Suzhou Zhangjiagang Scan the QR code on the poster to sign up Plastic flexible packaging is ubiquitous in our daily lives, from food preservation to express delivery. However, with the increasing severity of plastic pollution, the recycling of plastic flexible packaging has become a focus of social attention. Low recycling rate: In 2022, the scrap volume of plastic flexible packaging in China will be about 15 million tons, but the recycling rate is only 8.7. This is mainly because the materials of plastic flexible packaging are complex and diverse, mostly composite materials, which are difficult to separate and recycle. Difficulty in recycling: The thinness and easy contamination of plastic flexible packaging increase the difficulty of recycling. In addition, China's current plastic flexible packaging recycling system is still imperfect, lacking an...

-

ChinaReplas T&P 2025 The 3rd Plastic Pollution Prevention and Control Theory and Practice Forum Theme: Philosophy of Plastics Plastic pollution is not only an environmental problem, but also an economic problem . The root cause is that the market mechanism fails to fully reflect the full life cycle cost of plastics. Structural defects in key links such as market pricing, responsibility attribution and recycling systems have led to challenges in plastic pollution control. To solve this problem, it is necessary to carry out systematic reforms from an economic perspective and promote the transformation of the plastics industry to a circular economy through policy tools, market incentives and technological innovation. — 1 — Pricing failure: external costs are not internalized One of the core economic problems of plastic pollution is pricing failure ,...

-

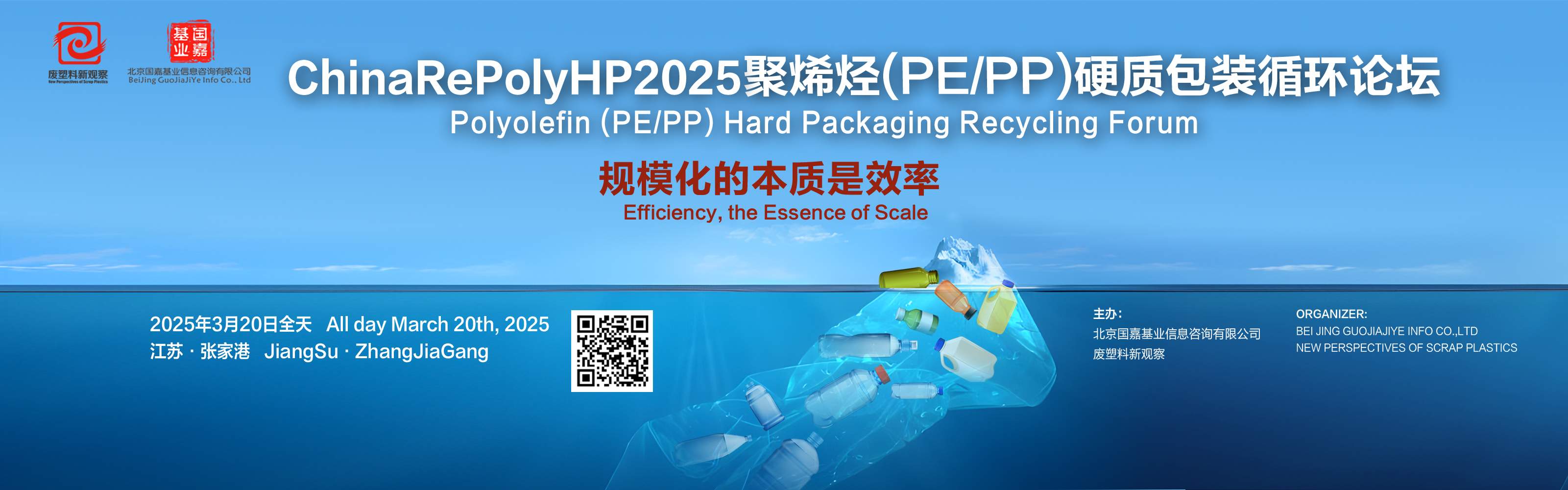

Theme of Polyolefin (PE/PP) Rigid Packaging Circular Forum: The essence of scale is efficiency Date: March 20, 2025 Location: Zhangjiagang, Suzhou According to a report by the United Nations Environment Programme: disposable plastics made from packaging account for the largest share of plastic waste in the world. 36% of all plastics produced by humans are used for packaging. According to statistics from Wood Mackenzie: In 2020, China used about 45 million tons of plastics for packaging production, nearly 40% of which were used to make rigid plastic packaging, among which polyolefin rigid packaging (PP/PE) grew rapidly. China's polyolefin (PP/PE) rigid packaging (bottles, pots, barrels, etc.) has formed a complete recycling flow due to its application scenarios (fast food boxes, milk jugs, seasoning pots, daily chemical bottles, etc.) and recycling metho...

-

From March 18th to 20th, 2025, ChinaReplas2025 China International Plastics Recycling and Regeneration Conference will be held in Suzhou Zhangjiagang ! Zhangjiagang is connected to the sea and has a large number of large-scale enterprises, developed port-related industries, and an extremely active open economy. It has attracted more than 40 "Fortune 500" companies to invest in more than 60 projects, and the number of foreign-funded enterprises exceeds 1,100. Therefore, it was rated as the best business city in mainland China by Forbes, and has been ranked among the top three of China's top 100 counties (cities) for 31 consecutive years. Zhangjiagang is a national civilized city with a unique transportation location. Through the Zhangjiagang Station high-speed rail, you can reach Shanghai Hongqiao Station in 1 hour; it only takes 1.5 hours to drive to Shanghai H...

-

Recycling plastics is an effective way to resolve the plastic environmental pollution crisis. High-quality recycling can retain the properties of plastics to the greatest extent possible. Through advanced technology, innovative processes and scientific management, waste plastics can be converted into recycled materials with high added value and in line with strict quality standards, thus achieving a gorgeous transformation of plastics from "waste" to "rebirth". — 1 — The Golden Apple Award: Recognition of excellence for high-quality regeneration The "Golden Apple Award" for high-quality recycling is a high recognition for companies and projects that have made outstanding achievements in the field of high-quality recycling. It will encourage more companies and scientific research institutions to invest in the exploration and practice of high-quality recycling...

-

ChinaReplas T&P 2025 The 3rd Plastic Pollution Prevention and Control Theory and Practice Forum The 3rd Plastic Pollution Governance: Theory and Practice Summit Theme: Philosophy of Plastics The Philosophical on Plastics — 1 — The Evolution of Plastics’ Historical Role 1950s-1970s: The darling of the industrial revolution Since the mass production of plastics in the 1950s, with its advantages of lightness, durability and low cost, it has quickly penetrated into core areas such as packaging, construction, and medical care, becoming a symbol of modern industrial civilization. By 2019, the annual global production of plastics has reached 460 million tons, a 230-fold increase from 70 years ago. During this period, plastics were regarded as the "king of convenience" and promoted the globalization of consumerism. 1980s-2010s: The tr...

-

The world's first: Plastic products "Design for Recycling" conference March 21, 2025 • Suzhou Zhangjiagang The national standard formulation project of "Plastic Recyclable Design Guide Part 1: Polyethylene Terephthalate (PET) Material" has been included in the third batch of recommended national standards plan in 2024 ( plan number: 20241703-T-606 ). This project is an important standard development task clearly defined in the relevant action plan of the State Administration for Market Regulation. At present, the draft of the standard has been completed and opinions are sought from experts, committee members, observers and relevant units. Please return your opinions and suggestions before March 24, 2025 . Scan the QR code to obtain the draft for comments — 1 — Background of Standardization In recent years, due to the popularity of d...

-

March 18-20, 2025 · Zhangjiagang In February 2025, the opening of a factory in northeast England attracted the attention of the global environmental protection community. This world's first commercial supercritical water plastic recycling plant, built by London startup Mura Technology , claims to be able to convert "non-recyclable" mixed plastic waste into recycled plastic raw materials, and is expected to subvert the limitations of traditional mechanical recycling and pyrolysis technologies. "Nature" magazine analyzed this technology in the form of a cover story, calling it "a new answer to the plastic pollution crisis." Editor's note According to OECD forecasts, global plastic waste will exceed 1 billion tons per year in 2060, while the current recycling rate is less than 10%. Mura's global expansion plan (building factories in 6 countries including Germany, th...

-

Within just a few months of its establishment, China Environmental Protection Group has demonstrated a positive development momentum: mergers and acquisitions of enterprises, leadership industry research, convening of science and technology innovation conferences, establishment of Tianjin Green Supply Chain Enterprise, and a 1 billion bet on Shenzhen... In the future, China Environmental Protection Group's in-depth layout in areas such as standard setting and international cooperation will bring new vitality to the industry and help China's resource recycling cause move to a higher level. In order to thoroughly study and implement General Secretary Xi Jinping's important speeches and instructions on energy conservation, carbon reduction and resource recycling, and conscientiously implement the decisions and arrangements of the Party Central Committee and the Sta...

-

Shenzhen Aibolu Environmental Protection Technology Co., Ltd. , as China's largest waste home appliance recycling platform, recently announced that it will invest in a large-scale renewable resource disassembly and recycling project in Fang County, Shiyan City, Hubei Province. The total investment of the project is as high as 1.2 billion yuan , aiming to further expand its business in the field of renewable resource recycling by building multiple advanced production lines. — 1 — Project Details Guangchun , co-founder and vice president of Aibolu , the project will mainly build the following production lines: Large appliance recycling and disassembly line: Build a new production line for recycling and disassembly of 1.5 million large appliances, covering the disassembly of various large household appliances. Air-conditioning compressor disassembly de...

-

Ambercycle is an ecosystem for circular textiles. Its molecular regeneration technology can transform discarded textiles into high-quality recycled polyester. Hangzhou Benma Chemical Fiber Spinning Co., Ltd. cooperates with Ambercycle to apply this advanced recycling technology to production, promote the transformation of the textile industry from the traditional linear economic model to the circular economic model , and achieve efficient use of resources and sustainable development. On January 7, Hangzhou Benma Chemical Fiber Spinning Co., Ltd. (hereinafter referred to as "Benma") officially held a strategic cooperation signing ceremony with Ambercycle of the United States, jointly committed to promoting the large-scale production of cycora® recycled polyester staple fiber. Cycora® recycled polyester is Ambercycle 's first high-end material solution usin...

-

The recycling rate of plastic flexible packaging is far below the average level due to its low recycling value, easy pollution and lack of consumer awareness. The "Plastic Flexible Packaging Recycling and Terminal Mixed Application Demonstration Project Based on Households and Recycling Companies" is a project funded by the United Nations Development Program Global Environment Fund Small Grant Program, and CPRRA is responsible for the planning and implementation of the project. The plastic flexible packaging collected by the community will be transported to plastic recycling factories and scientific research institutes to be processed into plastic products using advanced and feasible production technologies. On the morning of January 17, the Plastic Recycling Branch of the China Synthetic Resin Association (CPRRA) and the Reside...